Our Fenders

We take pride and are confident that our fenders are built stronger than anything else on the market.

How do we know? We have tested them. We took some of the standard fiberglass options on the market and have smashed them, burnt them, pulled them, froze them, and smashed them again. When we developed these fenders, we did lab testing of the fiberglass layup and did all of the same tests on our own fiberglass. Then we added foam and smashed ball bearings through them in the lab to determine exactly how much strength they had per square inch for impact resistance.

Finally, we did real world testing and ran them on some of the worst highways in North America and farm yards and other terrible places. We pulled heavy loads and light loads. We drove slow and we drove fast. We noted it all and built fenders that could withstand the daily requirements of the trucks.

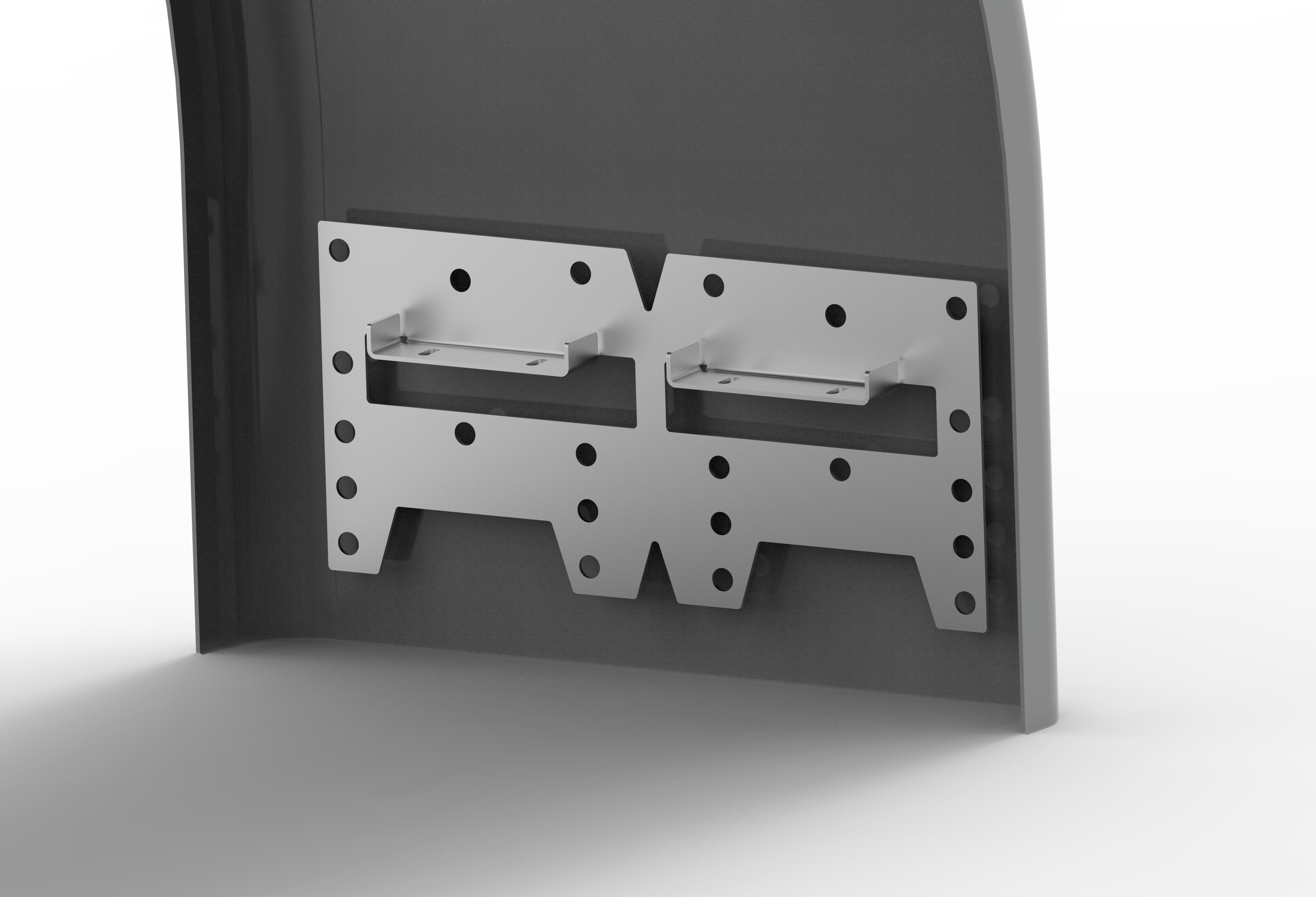

Our Mounting/Bracket System

Shift has developed the simplest bracket system on the market. Shift’s signature hidden bracket system utilizes 316 stainless steel internal brackets. These are bonded inside each fender and mated to 3/8” and ½” steel brackets that attach to the frame of the truck. These brackets slot together making installation easy. This saves truck downtime while installing and less money spent in the shop. It is great for shops, as it increases throughput of builds and lowers SRT’s.

Simple doesn’t mean weak. We use 3/8” and ½” steel brackets. We put the strength where we need it without adding additional weight where we don’t. Shift’s brackets have been tested for millions of miles with our test fleets and even more miles on the road with our customers. It is a proven system that is designed to last for the long haul.

No weld bracket system. The Shift signature hidden bracket system requires some drilling, but no welding. It requires basic shop tools and no fabrication experience.

We think of the installer as well as the end user.

Internal Lining System

After 13 years of producing the same great fender, we have disrupted the game with the first encapsulated liner out of closed cell foam. This liner is built directly into the fender and reduces the impact from stones and debris that come off the tires. The foam liner absorbs the impact and doesn’t transfer through into the painted surface. It’s like a built in shock absorber for your paint and reduces stars on the exterior of the paint.

The foam lining process took years to develop and refine. We worked with experts and labs throughout North America to find the right ratio of foam to fiberglass. Why did we bother with all this? To create a fender that is stronger and looks better for the long haul.

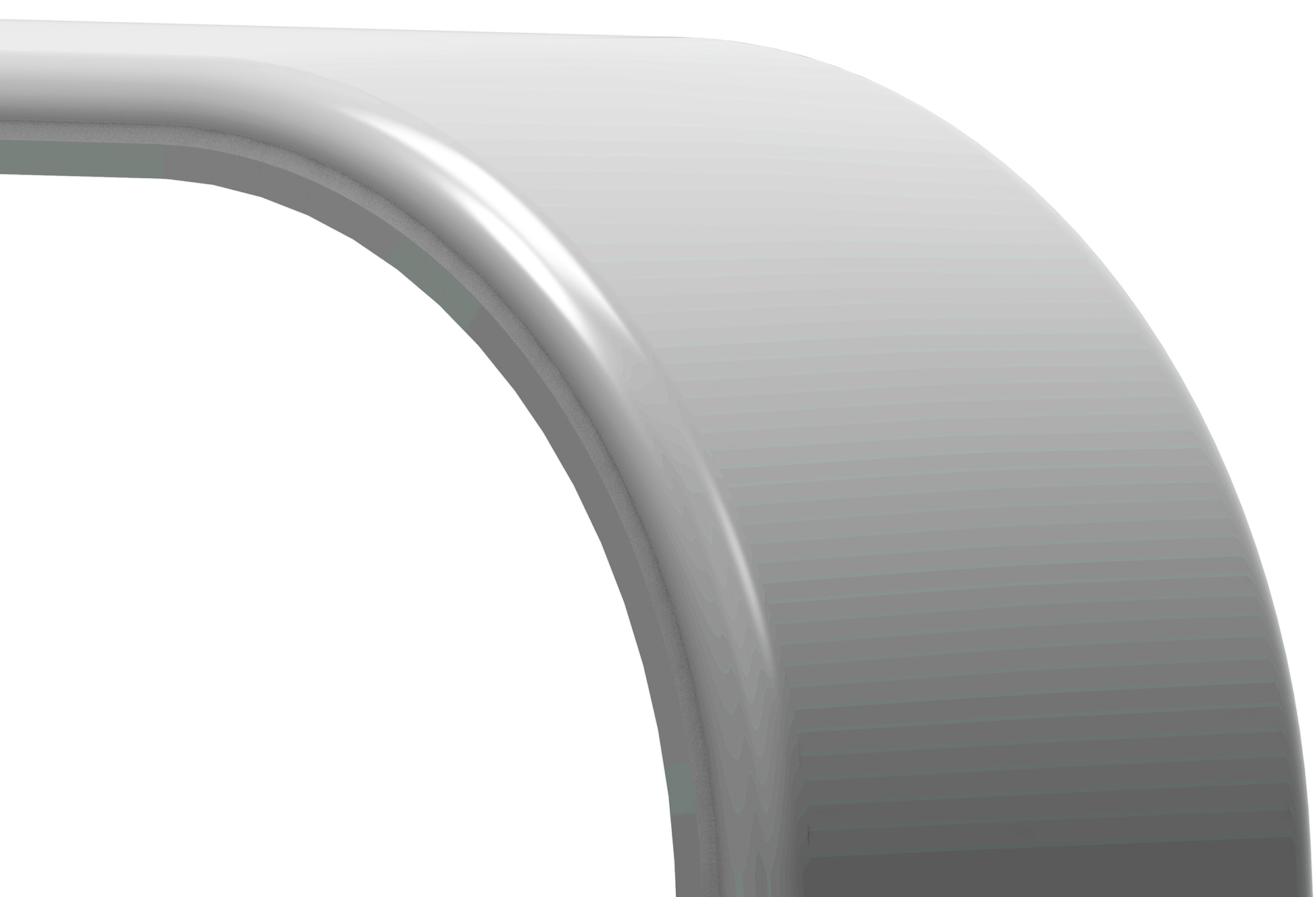

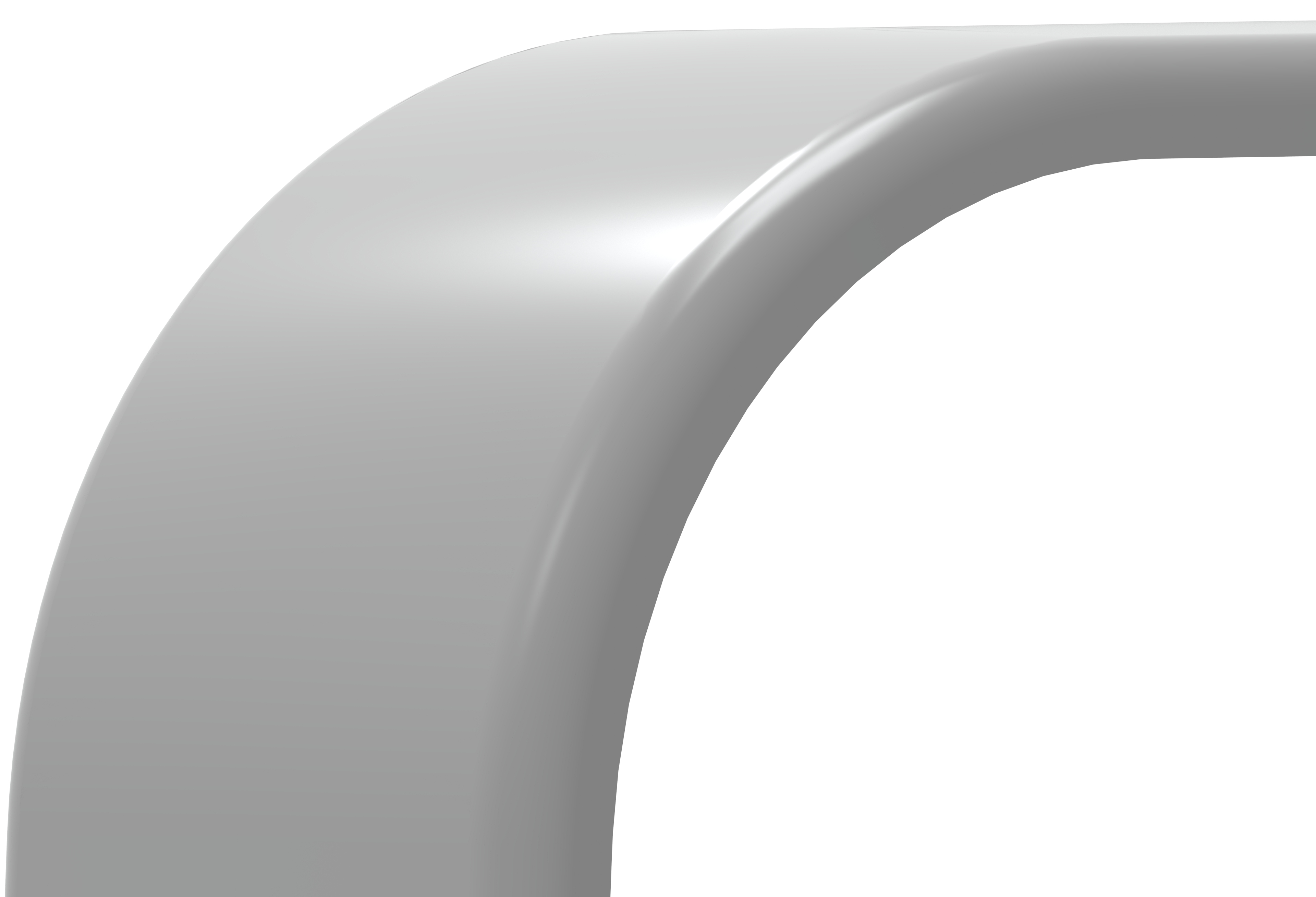

Peterbilt Feature Lip & Kenworth Feature Lip

Introducing for the first time in the industry, a fender that matches up with both a Peterbilt front fender and a Kenworth front fender. On one side of the fender, we have a feature lip that is designed to match the factory lip on your Peterbilt front fender. If you spin the fender around, it can also be mounted with the smooth side out to match the smooth side of the factory Kenworth front fender.

As always, these side profiles can be ordered in 3 different depths to let you achieve the look you are wanting. Starting with a low profile fender with a 1” lip. Or you can build it up to 2” lip or 3” lip to close that gap on your tires.

Shift Products fenders always maintain that the 1” lip fenders can have the tires removed without removing the fender. If there is an issue on the road, no one wants to take the fenders apart in order to fix their tire.